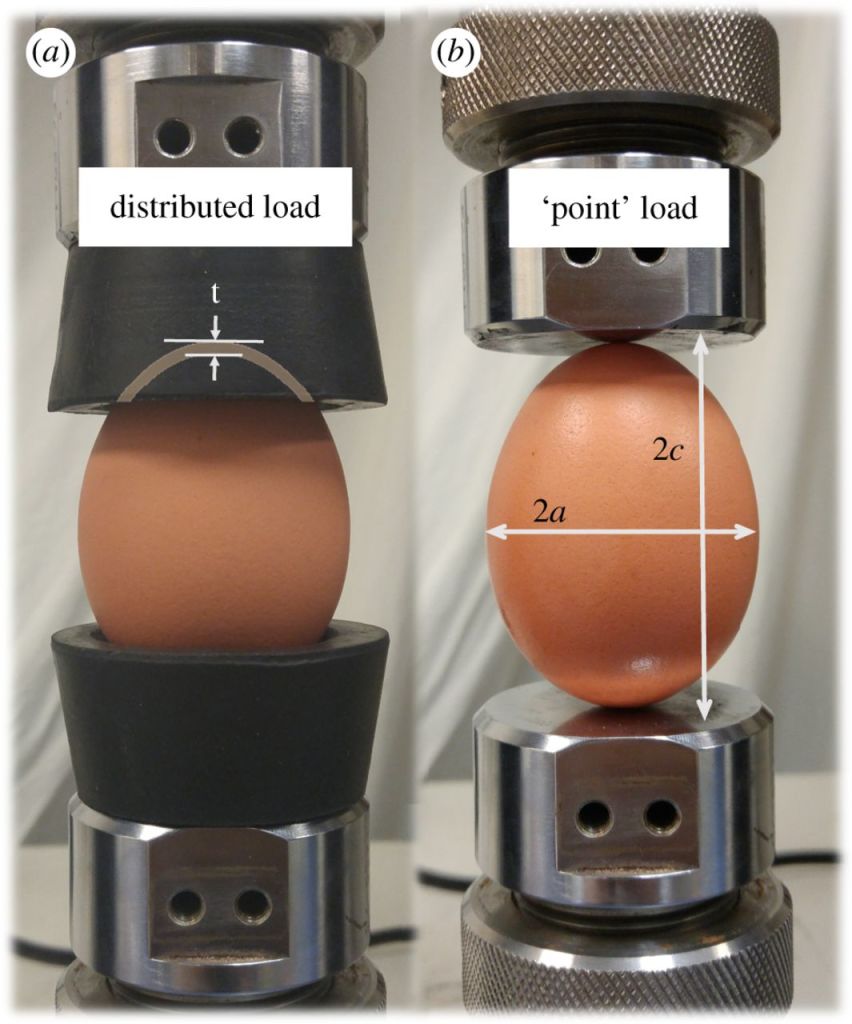

Testing a chicken egg: (a) Distributed load configuration: the applied normal load is transferred to the egg through rubber pads with a spherical cut removed from the centre. (b) Point load configuration. (Image via Hanh et al.)

Uncooked chicken eggs break easily if dropped or knocked against a hard surface; but if you try to break one by squeezing it between your palms, you’ll soon find yourself out of luck. Researchers were curious to find out what it is about the avian egg’s shape and the structure of the shell that allows them to withstand such pressure. They tested eggs from different species of birds of varying sizes – from quail eggs measuring only 30 millimetres tall, to ostrich eggs, which go up to 150 millimetres in height. Researchers applied pressure in two ways – distributed load and ‘point’ load – to imitate, respectively, the squeeze and the impact from a drop. They found that, the bigger the egg, the more force it can withstand; for example, ostrich eggs can resist the force of up to 5000 Newtons! These findings show that eggshells are the nature’s ceramics, and knowledge about the eggshell’s structure and resistance that can prove useful in developing strong pressure-resistant materials.

Authors:

Eric N. Hahn, Vincent R. Sherman, Andrei Pissarenko, Samuel D. Rohrbach, Daniel J. Fernandes, Marc A. Meyers

Corresponding author:

Marc Meyers, UCSD, Email: mameyers@ucsd.edu, Tel: 858-534-4719

Original paper published in Journal of Royal Society Interface on January 25, 2017.